In the mid-1990’s Future Fibres paved the way in the use of high-performance fibres in tensile cables. Initially in the marine yachting market, it first expanded into motorsport tethers and then other industrial applications.

Today, Future Fibres remains the world’s leading supplier of composite rigging to the marine industry, also delivering increasingly specialised solutions for a wide range of industrial applications.

Future Fibres’ understanding of formulating its technologies for specific performance characteristics has made it adept at innovating for some of the most challenging environments in the world, and at producing solutions which empower its customers to reach ambitious goals across wind energy, tidal energy, renewable energy, lifting equipment, civil engineering, aerospace and beyond.

Visit Booth 5 L 04 at JEC World to meet the experts from Future Fibres, and to see a range of high-performance fibre samples.

The booth will also feature a diverse set of case studies, showcasing the incredible breadth of possibilities with Future Fibres’ technology, including:

Cherenkov Telescope Array LST-1

The Cherenkov Telescope Array LST-1 is using intermediate modulus multistrand structural carbon cables from Future Fibres to address some of the most perplexing questions about astrophysics – seeking to understand the origin and role of relativistic cosmic particles, probe extreme environments, and explore physics frontiers.

High winds, high UV, salt in the air, and icing up, are all regular events at the telescope’s location, contributing to tough environmental conditions. The composite cables have performed exceptionally. LST-2 and following telescopes began construction in 2023. The Array will be using more than 100 telescopes spread between two sites in the northern and southern hemispheres.

flexC Carbon Ribbon Belt

This versatile, flexible belt combines high-performance carbon fibres with a uniquely flexible thermoset resin matrix.

In civil engineering, the flexC belt is used to strengthen concrete and steel elements in buildings, bridges, and other structures. It can be quickly deployed in emergencies, using adhesives to shore up compromised structures, or as a post-tensioning solution. Its precision and durability make it a champion in complex machinery too, ensuring flawless performance within high-fatigue environments, like wave energy PTO systems.

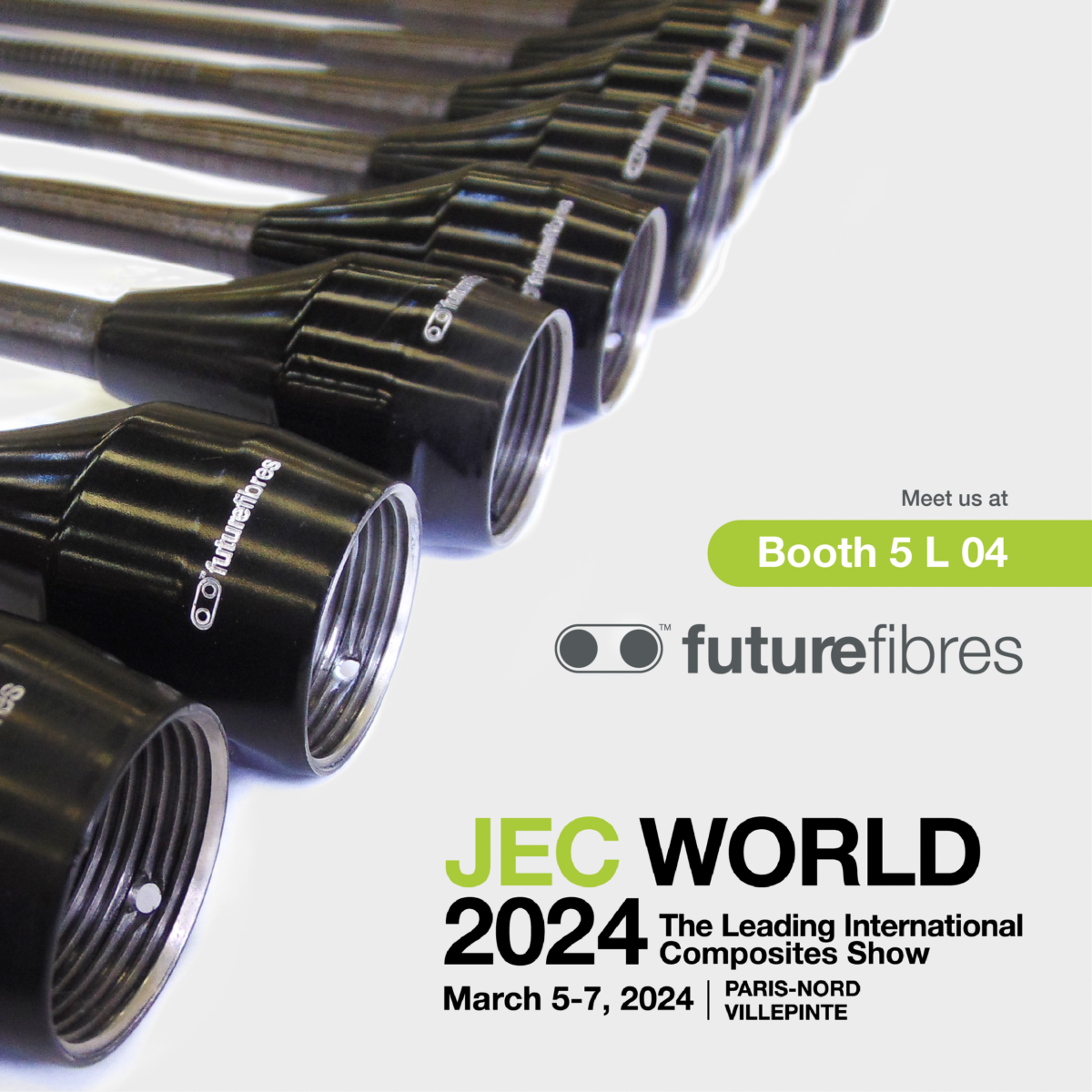

Crawler Crane Fibre Pendant

Aramid fibre cables for cranes are a break though in improving crane reach and staff safety. These lightweight, flexible fibre cables are used to build large wind turbines, reaching consistently high winds, resulting in a greater output of renewable energy. Replacing steel wire as the primary material for tension elements of crane rigging has greatly reduced boom weight and increased load lifting capacity and reach, as well as saving staff time and improving safety.

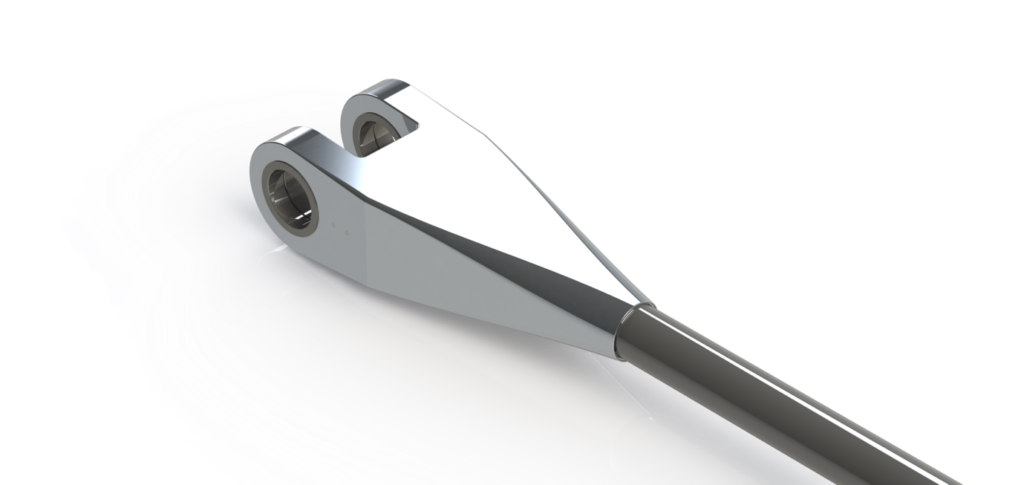

Barn Truss Tension Cables

Low and high tech combined perfectly for this customer who was provided with carbon truss ties to support an oak frame housing their collection of wine and Porsches. The cables serve to tie the arched shape of the oak frames together to stabilise the structure.

Detailed work on how the female threaded end of a Nanolite cone could interact with the oak frame. The use of double-acting rigging screws is providing significant tension adjustment as the building settles in the weeks, months, and years to come.

For more information on these projects and more, visit the Future Fibres booth (5 L 04) at JEC World.

To set up a meeting please email: [email protected]

For press enquires please email: [email protected]