Cables

Future Fibres cables provide significant performance advantages compared to traditional steel cables, with benefits such as weight reduction, improved fatigue resistance, extended cable life, no corrosion and reduced maintenance cost.

These characteristics deliver a lifetime cost reduction, providing the ideal upgrade for metallic solutions including crane pendants, aerospace, space, automotive, civil engineering, architecture, as well as emerging renewable energy technologies and many more.

| Fibre | Strength | Stiffness | Weight | Environmental | Fatigue | Cost |

| Aramid | X | X | X | |||

| UHMWPE | X | X | X | |||

| PBO | X | X | X | |||

| Carbon | X | X | X | X |

BRANDS WE WORK WITH

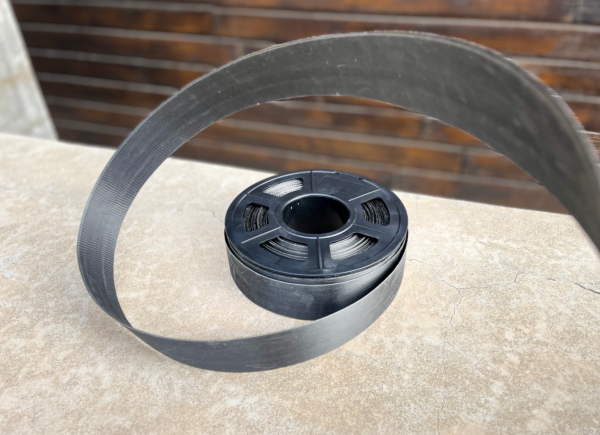

Strops, Slings and Tethers

Manufactured using our patented continuously wound unidirectional process, Future Fibres components can be found in numerous race cars, contributing to improved safety under FIA regulations. The same technique is used to manufacture high strength lifting strops, tethers, and slings up to 80m in length.

Quality assurance

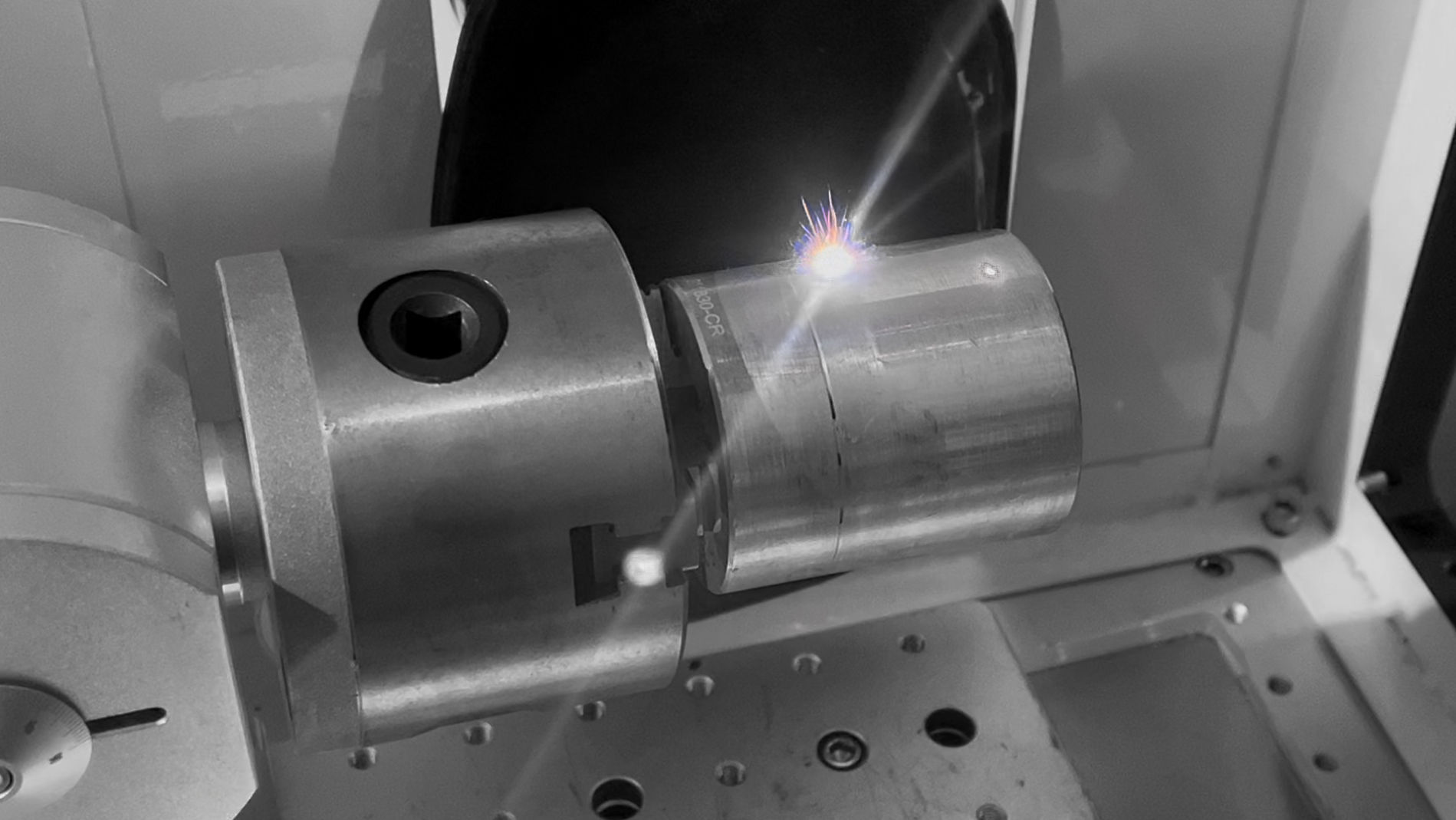

Future Fibres takes quality assurance very seriously. Our manufacturing facility is both ISO 9001:2015 and AS9100 certified. To ensure each cable is identifiable, and performs to desired specifications, all our cables are laser-etched with a unique serial number and client requirements.

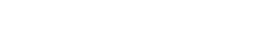

Flex C Belt

flexC belt is a highly versatile flexible belt, combining high performance fibres such as carbon fibre with a uniquely flexible thermoset resin matrix.

flexC belt is applicable to civil engineering, it can be used to strengthen and shore up concrete and steel structures such as beams, columns and webs as found in buildings, bridges and other structures. It can be quickly deployed in emergency situations with adhesives to shore compromised structures or used as a post-tensioning solution with end fastenings for ageing or structure’s experiencing a change of load case.

flexC belt has been deployed as a high-performance component within complex machinery, as a unique solution. Reliably delivering accurate repetition within an high fatigue environment, such as PTO systems in wave energy.