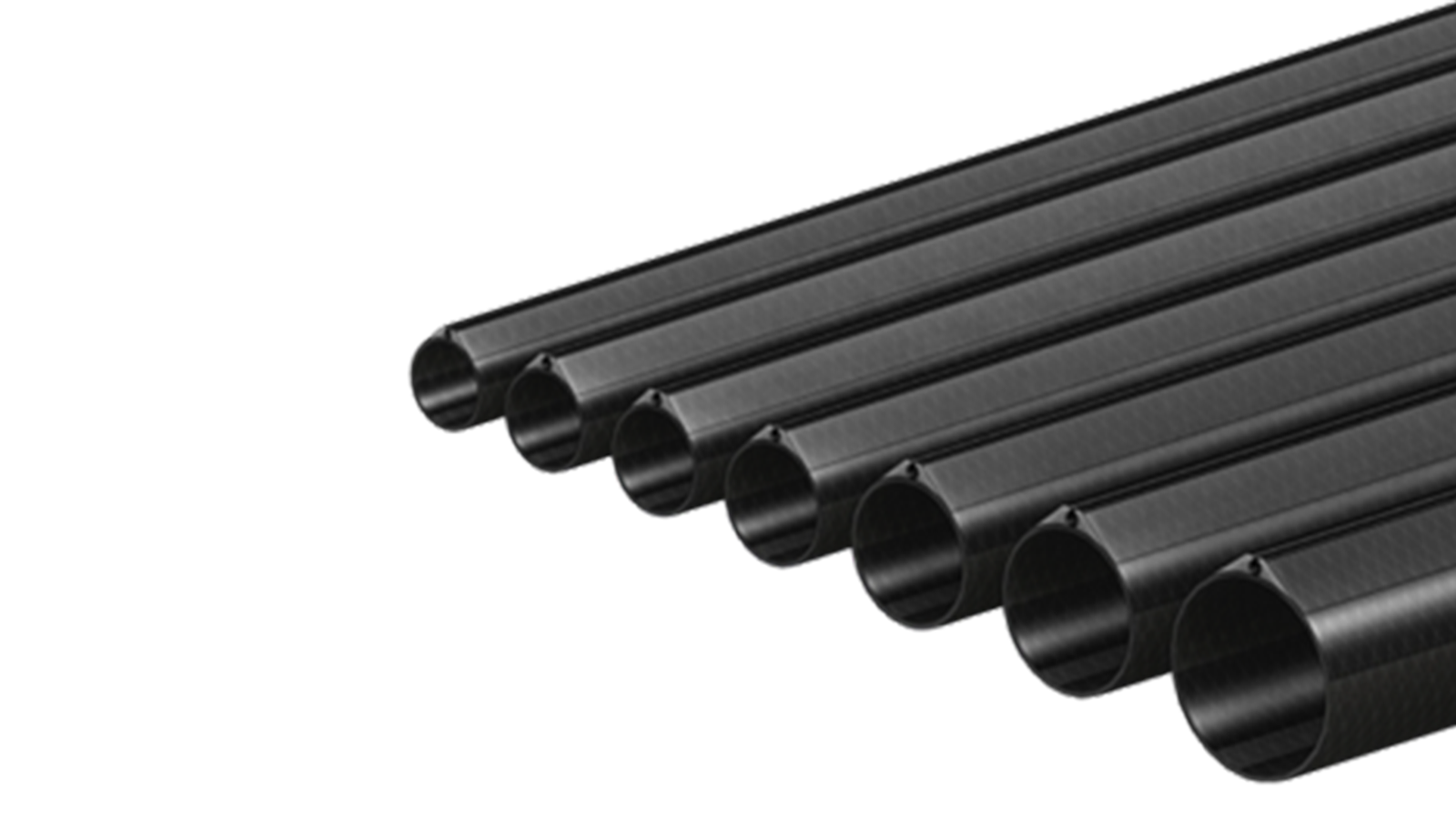

Future Fibres’ CF Foil range of headstay foils for furling jibs and genoas are a step ahead of the competition in their design and build quality. Engineered to have the ultimate torque transfer while protecting your sails and extending their life.

Tailor made for your yacht

Our foils are specifically engineered for each yacht, ensuring they perform at the required sail loads and torque for furling, as well as matching your headstay size and length.

Varying tube wall thicknesses optimise the foil for both strength and weight. Our tailored approach ensures foils comfortably tolerate foot and leech loads at each reefing point.

Features

Reliability

Engineered to be the strongest on the market, our carbon track has been designed with a superior internal section profile, reliably withstanding the luff loads generated from the sail. This has been proven repeatedly through extensive pull-out testing.

Weight savings

Up to 60% lighter than alloy foils.

Aesthetics - finish options

Satin finish comes as standard. Alternative finish options and colours are available.

Turnkey solution

A fully integrated package from design through to manufacture and installation.

Stay end fitting sizes are checked for size compatibility with the foil at the quoting and design stage. Bearings are cross referenced to ensure that they fit both the stay and the foil, bearings are dry fitted to the stay in our factory and are then shipped with the headstay.

Stay end fitting sizes are checked for size compatibility with the foil at the quoting and design stage. Bearings are cross referenced to ensure that they fit both the stay and the foil, bearings are dry fitted to the stay in our factory and are then shipped with the headstay.

Preserves your sails

A polished stainless steel feeder delivers reliable hoisting of the headsail and reduces the chance of damage to the luff tape. Once hoisted, the feeder assembly can be removed from the foil until the next time the sail is lowered.

Maximum strength

Tapering the joins between foil sections ensures the best possible join quality between sections and allows for more efficient torque transfer throughout the system.

The tapered join ensures the optimum glue film thickness and pressure in the glue joint during the assembly process.

Glue thickness is an important aspect of making a good bond, as is the expulsion of air that is achieved by bringing the two mating conical sections together under pressure during the assembly.

Not sure what your looking for, get in touch with us and we’ll help you.