About the Project

In 2021 Tanjung Boulevard of Malaysia contacted Future Fibres to source high performance cables.

The Challenge

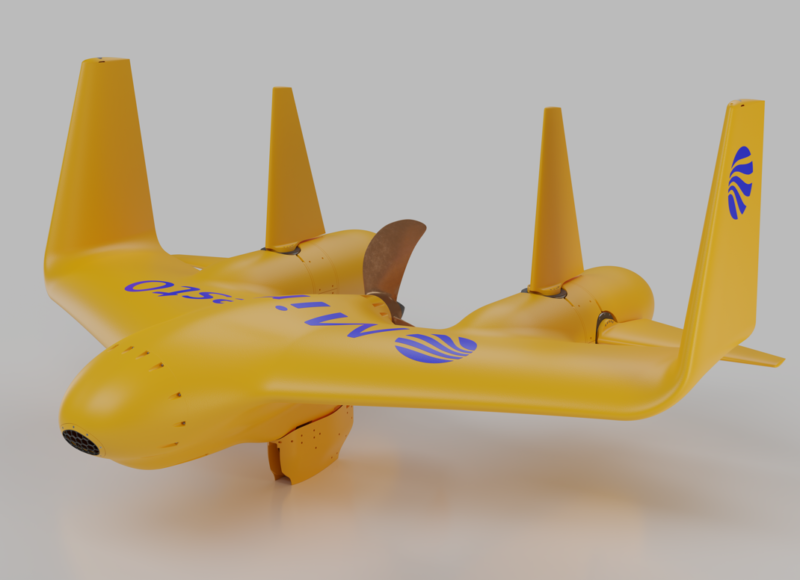

Malaysia is subject to heavy flooding in the rainy season. Remote locations, often with single access roads, can be cut off from supplies for extended periods due to damaged or destroyed bridges. By swiftly deploying BR90 temporary bridging the Malaysian Government can support isolated communities.

The Solution

Used in sets of four, 48 Aramid tensile cables were rigged under aluminium bridge segments and coupled with hydraulic tensioners. Once under tension and locked into place the cables brace the bridge, allowing vehicles to pass over.

Facilitating effective transportation demanded low weight properties, and effective deployment meant that accurate control was essential – the cables were required to provide adequate stretch to allow them to be stretched into position by hydraulics (in as little as 45 minutes). Added to this, the tensioned bridging system supports heavy armoured vehicles – it is rated to MVLC 70 – allowing vehicles of up to 70 tons to cross.

Why Aramid?

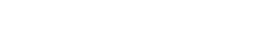

To perform to these exacting standards, Future Fibres selected a 58.5mm diameter K49 Aramid core. Aramid provided the ideal combination of stretch, strength and low weight required. With a 4mm thick plastic jacket, and precise custom-designed steel spike and cone end fittings, the final product weighed in at just 3.5kg per metre.

Standing Up To The Elements

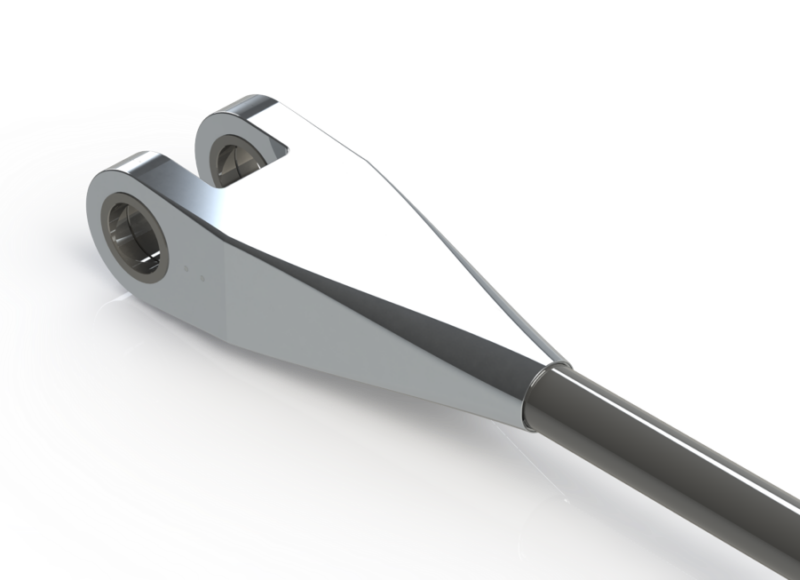

As well as intense loads, the cables were required to stand up to the natural rigours of rural Malaysia in the rainy season. The cables’ thick plastic sheave was added to protect the structural fibre from water, dirt, UV, and handling, whilst remaining supple and coil-able onto drums for transportation.

First-Hand Approval

Future Fibres was pleased to host officers from Malaysia at its production facility in Valencia, where we conducted a proof test.

Future Fibres was on the ground in Malaysia for one week assembling and completing a final acceptance test on the BR90 bridging alongside the customer.

“We’re delighted to have produced a product that performs to such specific and demanding specifications. This project was extra-rewarding as our hard work has gone towards supporting this important temporary bridging system.”Richard Adams, Business Development Director, Future Fibres

Working in an industry which could benefit from high-performance tensile cables? Future Fibres has worked in industries from aerospace, to civil engineering, to architecture, motorsport and beyond – learn more about industrial applications, or get in touch with an expert.